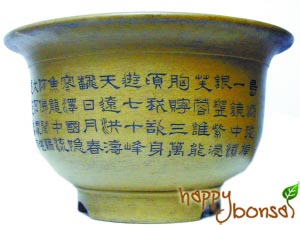

Bonsai is tree in small pots, and these bonsai pots are mostly made in Japan or China. Japanese pottery is known for its high quality. They are elegant, natural, often unglazed, and fairly expensive. On the other hand, Chinese pottery is generally cheaper (while their quality is getting better and better) and often brightly glazed. Most of these bonsai pots are made of high-quality clay and are baked in high temperatures; hence these bonsai pots can tolerate very low and high temperatures.

However, what I just mentioned is only in the context of bonsai pots of low and medium quality. For the highest, world-class quality bonsai pots, the picture is different. Many of the top bonsai pots are made in China. In fact, today, many Japanese bonsai enthusiasts still prefer Chinese pots, especially kowatari containers.

Same as the art of bonsai, the origin of bonsai pottery is China. As early as the 12th century, without the knowledge we have in chemistry today, Chinese ceramists were able to make beautiful bonsai pots with amazing quality which modern technology cannot even match with today.

A major different between Chinese and Japanese bonsai pots lies in the production method. Although the Japanese bonsai pots are handmade, they are shaped in a mould. The clay is pressed into a pre-shaped mould and the interior of the pot is shaped manually. On the other hand, the Chinese use an inside mould that only serves as a framework for the clay. The exterior is shaped by hand, and this allows the ceramists to create countless shapes and designs.

The bonsai pot should enhance the bonsai tree and not be overpowering or a dominant feature. It should harmonize and complement the characteristics of the bonsai tree, showing the bonsai off to its best advantage.

Although the Japanese bonsai pots are handmade, they are shaped in a mould. The clay is pressed into a pre-shaped mould and the interior of the pot is shaped manually. On the other hand, the Chinese use an inside mould that only serves as a framework for the clay.

yes, one is called hump and the other is slump molding. they’re both molding processes, so they’re actually the same. the process sounds exactly the same except one uses interior and one uses exterior. you might differentiate further by explaining a bit more otherwise it just sounds like there is no difference.

This topic baffles me too. It is surprising to me how some Japanese pots are still considered valuable even though one might consider being of poor workmanship (e.g. uneven surface / poor application of glaze). Some people swear by it because of “special clay” that is used. Although the clay has a rough texture but the pots doesn’t break in the harshest winter. Some Chinese pots such as the unglazed pots from Yixing, one might consider being of excellent quality because of the purple sand clay, but still selling at a lower price. Perhaps the answer lies in what is “percieved” as high quality, and not so much where the pot is made?

Yes, Kenny, I agree indeed 🙂

Personally, I’ve found some excellent pots both of Chinese and Japanese origin. Chinese pots tend to appeal to me more, because they seem to be more adventurous in the shape of the pots as well as in the motifs on pots. I am curious about the kowatari pots Sandy mentions. I’m going to have to research these out of curiosity.